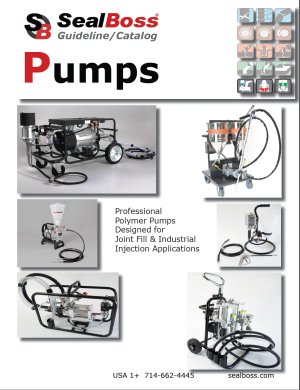

SLP 3C Acrylate Gel Injection Pump

Pneumatic Plural Component Pump

for Acrylate / Acrylic Gel Injection Applications

Advantages

- Stainless steel (material contact)

- 2 Plus 1 component

- Water flush pump built-in

- Extremely light-weight design

- Robust, heavy duty components

- Large material passages for use of products with higher viscosities

- Piston seals do not require tensioning

- Easy maintenance and repair

- Pneumatic design

Range of Applicable Materials

- Polyacrylate gel

- Polyurethane resin

- Polyurethane foam grout

- Aqueous solution

Product Description

The SealBoss SLP 3C two plus one component, pneumatic reciprocating piston injection machine is a new addition to our signature line of professional and purpose built heavy duty injection pumps. All internal pump parts in contact with product are made from stainless steel.

This pump offer a two component product setup and a built-in water pump to flush acrylate gel pump directly after use. The product pums are set to a 1:1 mixing ratio by volume. Product is fed directly from the product containers via suction tubes. Pressure hoses and applicator are supplied with the machine. Our pneumatic pumps are easily maintained, highly reliable and very easy to use. Air flow is effortlessly controlled and our pumps perform very well at low and high rates of product flow. Our pumps feature relatively large internal clearances in the major fluid passages (i.e. large intake and discharge openings), that allow liquids of higher viscosities to pass.

Air-powered pumps have been highly developed to provide long-term reliability and durability even under difficult injection conditions. With the air-powered design there is inherently less mechanical load and wear on key components than with other designs. Long term durability is achieved by the relatively low-speed, high clearance nature of the moving parts. Air-powered pumps have a unique advantage in their ability to throttle back flow to meet changing site needs. Stop/start cycle limitations do not apply to these pumps, so no adjustments need be made when dispensing rates decrease; the air-powered pump will function as intended, at a reduced refill/discharge cycle rate. If pump output rate reduction is desired, the applied air pressure can be easily adjusted downward with the provided regulator.

With air-powered pumping systems, airlines are run to the pump instead of electricity, which provides immediate benefits in simplicity and safety. Pumps are delivered as a complete system, with all the necessary tubing, connectors and applicators.