Slab Lifting

Polyjacking | Foam Jacking

Slab Lifting Systems

Soil Stabilization Systems

Concrete Leveling, Lifting and Void Filling

Polyurethane Foam

SealBoss Slab Lifting Foams, Pumps, Systems

Slab Lifting with polyurethane concrete jacking foam for the purpose concrete slab leveling is also known as Polyjacking and Foam Jacking. Concrete slab lifting is achieved by injecting SealBoss structural polyurethane concrete lifting foam into voids beneath settling or uneven concrete slabs with the purpose of support and lift. Polyjacking is a proven concrete leveling method to stabilize, void fill and provide foam concrete lift without excavation and without adding much additional weight to the substrate.

Existing concrete slabs indoors and outdoors can be lifted or foam jacked to their original position utilizing the SealBoss Slab Lifter System and expanding concrete jacking foam products.

The process of slab jacking, foam jacking, polyurethane concrete raising, poly jacking or poly leveling uses chemical grouting techniques and chemical polyurethane grouts and offers many advantages over conventional mud jacking.

Foam jacking is used in industrial and residential markets.

Foam jacking is the cleanest and fastest concrete lifting and stabilization process. Only very small port holes are required. Drilling is clean and fast due to the small diameter hole size.

Foam jacking is the quietest and fastest process for stabilizing and raising settled concrete slabs.

Lightweight high strength, high density polyurethane foam reduces the overburden on underlying soils, reducing the chances for re-settlement. High density polyurethane is waterproof, so treated slabs are thoroughly undersealed and protected from washout.

Advantages of chemical grouting for slab lifting and stabilization:

- Quick and easy process with minimum mess and inconvenience

- Minimal invasive, very small port holes to inject product through slab

- Minimal disruptive

- Low unit weight, easy to transport to jobsite

- Stabilizes base and strengthens slab Combine with subgrade soil stabilization for permanent results

- Erosion control

- Less costly than replacement

- Based on scope work can be done in hours/days

- Quick set time

Product Quick Reference

Concrete Slab Lifting Pump and Starter Kit

Heated Polymer Lifting & Void Filling

Poyurethane Foam Injection, Polyjacking, Slab Lifting, Concrete Lifting, Foam Sprayer

The SealBoss PolyLifter Pro2 Pump System is an affordable and compact pump for new and experienced contractors. The entire system can easily fit in the back of a pickup truck. The set up is simple and requires minimal equipment.

- PolyLifter PRO 2 PUMP PAGE - AVAILABLE SOON

- DATA SHEET PDF - AVAILABLE SOON

- Max output flow up to 5 gal / min

- Mixing ratio 1:1

- Heating power 7.5KW

- Heating temperature max. 175 F, 80 C

- Max heating hose length 250 ft, 75m

- Working pressure max. 1600psi , 11Mpa

- Air Intake max. 120 psi, 0.8Mpa | max 0.9m³/min

- Voltage: 110v 50/60Hz

STAINLESS STEEL

Dimensions

12″

36″

60″

SealBoss Void Fill Pump Systems are affordable, portable, light-weight machines for new and experienced contractors. The entire system can easily fit in the back of a pickup truck. The set up is simple and requires minimal equipment.

The SealBoss ® SLP 2C-5G Cart System is an affordable, portable for new and experienced contractors. The entire system can easily fit in the back of a pickup truck. The set up is simple and requires minimal equipment. Available with Generator/ Air Compressor Combo.

The SealBoss ® P3003 Portable System is a low cost, extremely portable small job system for low volume injection for slab support with minimal or no lifting requirements.

The SealBoss ® P3003 Portable System in use at a wholesale warehouse to stabilze the concrete slab. Here shown in combination with the SealBoss QuickFix 6060 Floor Spall Repair and 6500 Joint Filler System.

IMPORTANT: For void fill and slab lifting applications with unheated equipment some limitations may apply. Please be advised that depending on ambient and substrate conditions, SealBoss 1600 line foams may need to be temperature conditioned prior to use. Please consult with your SealBoss technician for details.

SealBoss ® Deep Soil

Soil Compaction, Void Fill, Slab Lift Injection System

DeepSoil Lift™ Aplications:

Soil densification and encapsulation

- Settled buildings, warehouses

- Pipe and tunnel segments

- Bridge abutments

- Highway approach slabs

- Concrete, rigid and flexible pavements

- Ports, airports, bus stations

- Lift stations

- Equipment pads

When Slab Lifting is not enough:

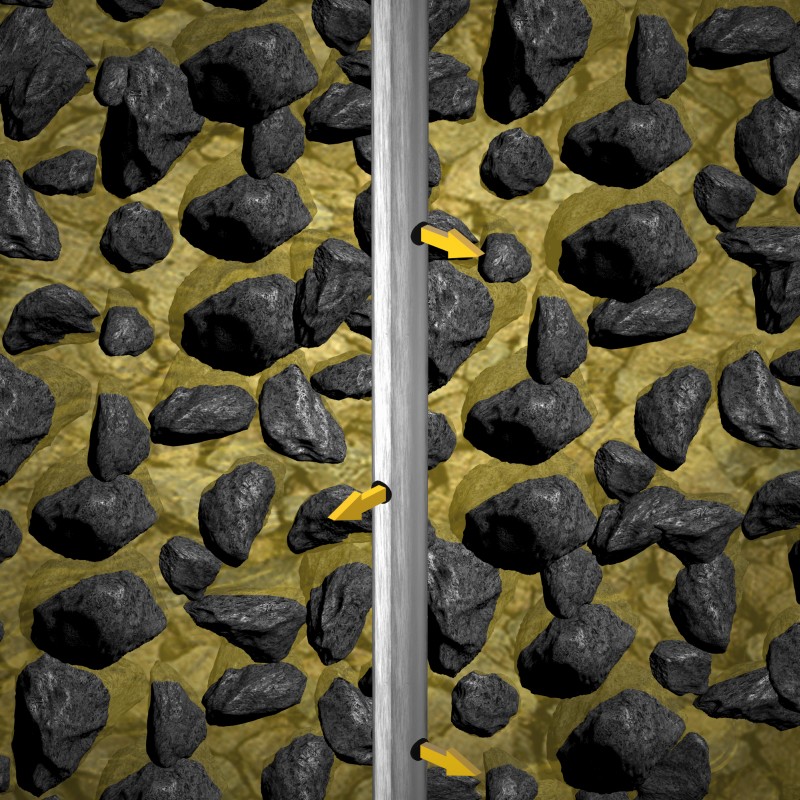

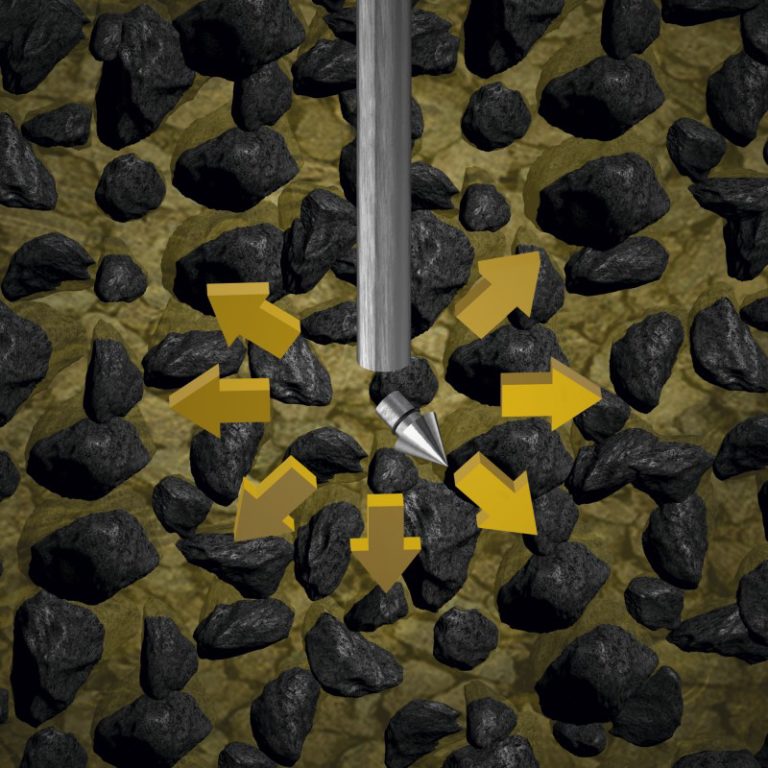

DeepSoil Lift™ (DeepSoilLift.com) is a polyjacking / foam jacking polyurethane foam injection system process utilizing a SealBoss injection pump and injection lance setup to reach deep into the soil to below grade pockets of unstable soil up to a depth of 30 feet (10 meters) with the purpose of densification and compaction.

The DeepSoil Lift™ process is useful for certain structures and flexible pavements where it can be applied in conjunction with conventional slab lifting.

A thorough site evaluation prior to injection is recommended. This may include soil borings, Dynamic Cone Penetration (DCP) testing, Ground Penetrating Radar or Structural Radar (GPR) as necessary. Based upon data, grid spacing and injection depths are determined. Install SealBoss Injection Lances to the correct locations and depths. Inject with SealBoss 1600 series structural foam polymer monitoring for lift, pressure and consumption.