Exploring the Versatility of Grout Injection Packers

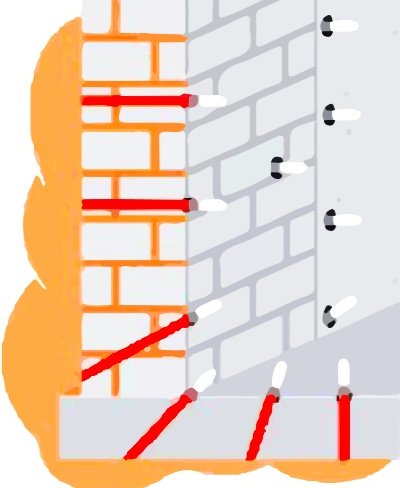

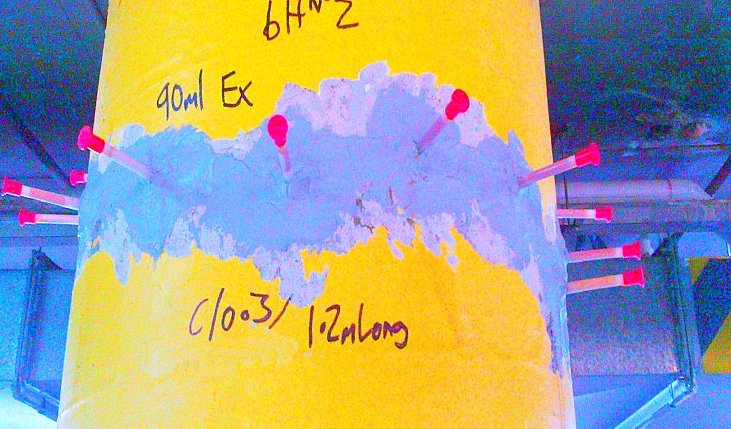

Grout Injection Packers, also commonly referred to as Packers, Ports, or Injectors, serve as essential tools in the field of construction and repair, particularly in the context of crack injection and leak sealing.

To clarify their various applications and types, these packers are often accompanied by descriptors such as Grout, Epoxy, Mechanical, and Surface, leading to specific terms like Mechanical Packers, Epoxy Injectors, and Surface Ports.

The lexicon of packer terminology extends even further as injection professionals devise elaborate combinations of terms to precisely describe their equipment. For example, phrases like Mechanical Injection Packers, Plastic Grout Injection Ports, and Epoxy Crack Injection Plastic Surface Nozzle Ports with Perforated Tri Base Design and Extra Long Anti Leak Plastic Caps, though complex, provide insiders with valuable specificity about the tool’s design and functionality.

In our video below, we demonstrate the particulars of the Plastic Button Head Packer, a tool also recognized in the industry under names such as Progressive Screw Injector, Port, Packer, Top Hat Packers, or Easy Slide Packers. These names reflect the packer’s unique features, such as its compatibility with button head or slide couplers.

Furthermore, we introduce the Hammer-In Packer, an alternative known variously as Hammer-In Port, Bang In Packer, or Hammer Blow Injector. This variation emphasizes the packer’s method of installation, which involves a simple, forceful action to position the packer into place.

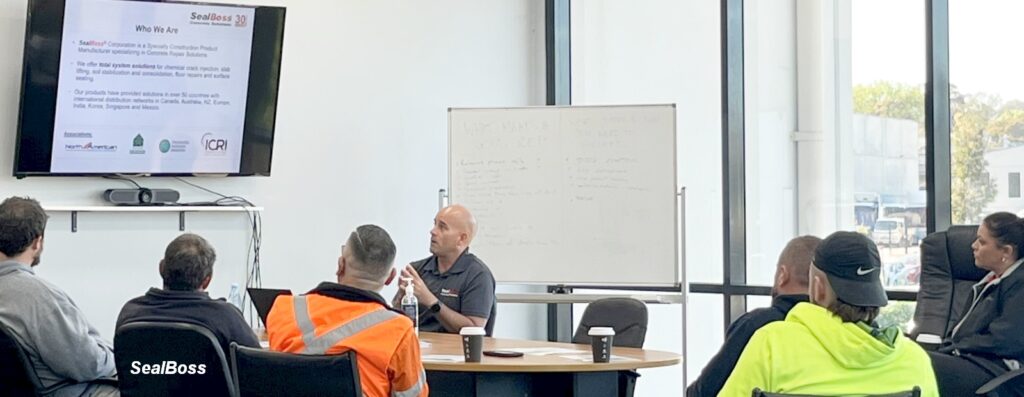

SealBoss® stands at the forefront of this industry as a premier international supplier of both packers and surface ports. Our extensive selection includes surface-mounted epoxy injection ports compatible with all SealBoss epoxy injection systems. Whether you’re working with handheld manual gun injection, pneumatic gun injection, epoxy pump injection, cartridge injection, or high pressure zerk coupler connected epoxy injection, our products are designed to meet your project’s specific needs.

By offering this array of sophisticated and versatile tools, SealBoss® caters to the diverse demands of the construction and repair industry, ensuring that professionals are equipped with the right packers and ports for every situation.