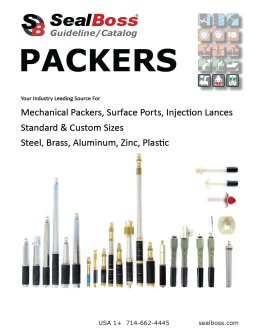

Injection Packers

Mechanical Injection Packers | Surface Mount Ports

Grout Injection Lances & Needles | Accessories

Table of Contents

Your Industry Leading Source for Injection Packers

Mechanical injection packers and injection ports are key to a successful injection process. We strive to provide the most comprehensive and diverse injection packer selection in the industry. Our vast inventory is tailored to meet varied customer needs and job requirements, ensuring swift delivery times.

For over three decades, we have been supplying millions of injection packers to companies worldwide, each adapted to their unique needs and requirements. We offer a wide range of packer material types, diameters, lengths, ball and valve designs, to ensure the ideal match for your project. If you require a bespoke design for a specific application, we also provide manufacturing services to meet your unique specifications.

Steel Packers

- SealBoss ® 13-60S Steel Injection Packer | Video

- SealBoss ® 13-60S Button Head Steel Injection Packer | Video

- SealBoss ® 13-115S Steel Injection Packer | Video

- SealBoss ® 13-115S Button Head Steel Injection Packer | Video

- SealBoss ® 13-175S Steel Injection Packer | Video

- SealBoss ® 13-175S Button Head Steel Injection Packer | Video

- SealBoss ® 16-60S Steel Injection Packer | Video

- SealBoss ® 16-115S Steel Injection Packer | Video

- SealBoss ® 16-70 EZ-FIT Steel Injection Grout Packer | Video

- SealBoss ® 16-70 EZ-FIT Button Head Steel Injection Grout Packer | Video

- SealBoss ® 16-60S Steel Injection Packer | Video

- SealBoss ® 16-60S Button Head Steel Injection Packer | Video

- SealBoss ® 16-115S Steel Injection Packer | Video

- SealBoss ® 16-115S Button Head Steel Injection Packer | Video

Zinc Packers

Brass Packers

- SealBoss ® 6-46B Brass Injection Packer | Video

- SealBoss ® 8-50B Brass Injection Packer | Video

- SealBoss ® 10-60B Brass Injection Packer | Video

- SealBoss ® 10-105B Brass Injection Packer | Video

- SealBoss ® 10-200B Brass Injection Packer | Video

- SealBoss ® 10-300B Brass Injection Packer | Video

- SealBoss ® 13-70B Brass Injection Packer | Video

- SealBoss ® 13-100B Brass Injection Packer | Video

- SealBoss ® 13-200B Brass Injection Packer | Video

- SealBoss ® 16-70B Brass Injection Packer | Video

- SealBoss ® 16-200B Brass Injection Packer | Video

Aluminum Packers

Plastic Packers / Ports

- SealBoss ® 5/8BH Button Head | Hammer In | EZ Flow Plastic Injection Packer | Video

- SealBoss ® 5/8BH Zerk | Hammer In | EZ Flow Plastic Injection Packer | Video

- SealBoss ® 3/8 Hammer In Plastic Injection Packer | Video

- SealBoss ® Surface Mounted Plastic Port with Zerk Fitting | Video

- SealBoss ® Epoxy Port | Surface Mount Plastic Tri Base Port | Video

- SealBoss ® Epoxy Corner Port | Surface Mount Plastic Corner Port | Video

- SealBoss ® Epoxy Port | Drill Hole Recessed Mount Surface Port | Video

Couplers / Fittings

Needles / Lances

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 3”

13 x 60mm

Standard Packer with Zerk Style Fitting

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 3”

13 x 60mm

Standard Packer with Buttonhead

Buttonhead version of standard mechanical packer for most secure and stay in place connection and reduced leakage at coupler. Anti return valve in buttonhead permits port-port travel technique by removing the fitting. Optional zerk fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 4”

13 x 115mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 4”

13 x 115mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Buttonhead version of standard packer for most secure and stay in place connection and reduced leakage at coupler. Anti return valve in buttonhead permits port-port travel technique by removing the fitting. Optional zerk fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 6”

13 x 175mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

1/2” x 6”

13 x 175mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Buttonhead version of standard grout injection packer for most secure and stay in place connection and reduced leakage at coupler. Anti return valve in buttonhead permits port-port travel technique by removing the fitting. Optional zerk fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

5/8” x 3”

16 x 70mm

EZ-FIT Large Diameter Washer Packer

Fitted with a larger washer this mechanical packer can be placed easily and precisely each and every time into the drill hole. The washer prevents the packer from sliding too far into the drill hole. Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

5/8” x 3”

16 x 60mm

Larger Diameter Packer with Zerk Style Fitting

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

5/8” x 3”

16 x 60mm

Larger Diameter Packer with Buttonhead

Buttonhead version of standard packer for most secure and stay in place connection and reduced leakage at coupler. Anti return valve in buttonhead permits port-port travel technique by removing the fitting. Optional zerk fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

5/8” x 4”

16 x 115mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL MECHANICAL INJECTION PACKER

STEEL

Dimensions

5/8” x 4”

16 x 115mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Buttonhead version of standard packer for most secure and stay in place connection and reduced leakage at coupler. Anti return valve in buttonhead permits port-port travel technique by removing the fitting. Optional zerk fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

1/4” x 1.8″

6 x 46mm

Super Small Packer

Bottom anti-return valve permits removal of head prior to patching drill holes. Small diameter ideal for grout line drilling and shallow drill angles. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

5/16″ x 2″

8 x 50mm

Very Small Packer

Bottom anti-return valve permits removal of head prior to patching drill holes. Small diameter ideal for grout line drilling and shallow drill angles. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

3/8″ x 2.5″

10 x 60mm

Small Packer

Bottom anti-return valve permits removal of head prior to patching drill holes. Small diameter ideal for grout line drilling and shallow drill angles. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

Bestseller – a SealBoss Standard

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

3/8″ x 4″

10 x 105mm

Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Bottom anti-return valve permits removal of head prior to patching drill holes. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

3/8″ x 8″

10 x 200mm

Very Long Packer

Designed to move point of injection deep into the structure to bridge over voids or gaps. Bottom anti-return valve permits removal of head prior to patching drill holes. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

3/8″ x 12″

10 x 300mm

Extremely Long Packer

Designed to move point of injection deep into the structure to bridge over voids or gaps. Bottom anti-return valve permits removal of head prior to patching drill holes. Only small diameter drill holes needed. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

1/2″ X 3″

13 x 70mm

Standard Brass Packer with Zerk Style Fitting

Bottom anti-return valve permits removal of head prior to patching drill holes. Suitable for PU, EP, and Silicate grouts.

Bestseller – a SealBoss Standard

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

1/2″ X 4″

13 x 100mm

Longer Brass Packer with Zerk Style Fitting

Bottom anti-return valve permits removal of head prior to patching drill holes. Suitable for PU, EP, and Silicate grouts.

Bestseller – a SealBoss Standard

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

1/2″ X 8″

13 x 200mm

Very Long Brass Packer with Zerk Style Fitting

Bottom anti-return valve permits removal of head prior to patching drill holes. Suitable for PU, EP, and Silicate grouts.

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

5/8″ X 3″

16 x 70mm

Standard 5/8″ Brass Packer with Zerk Style Fitting

Bottom anti-return valve permits removal of head prior to patching drill holes. Suitable for PU, EP, and Silicate grouts.

Bestseller – a SealBoss Standard

BRASS MECHANICAL INJECTION PACKER

BRASS

Dimensions

5/8″ X 8″

16 x 200mm

Very Long Brass Packer with Zerk Style Fitting

Bottom anti-return valve permits removal of head prior to patching drill holes. Suitable for PU, EP, and Silicate grouts.

ALUMINUM MECHANICAL PACKER

ALUMINUM

Dimensions

3/8″ X 3″

10 x 80mm

Small Diameter Packer

Economical packer with removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

ALUMINUM MECHANICAL PACKER

ALUMINUM

Dimensions

3/8″ X 4″

10 x 100mm

Small Diameter Longer Packer for Steep Angle Drilling and Deteriorated Substrates

Economical packer with removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

ALUMINUM MECHANICAL PACKER

ALUMINUM

Dimensions

1/2″ X 3.5″

13 x 80mm

Standard Packer

Economical packer with removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

ALUMINUM MECHANICAL PACKER

ALUMINUM

Dimensions

1/2″ X 4″

13 x 100mm

Standard Packer

Economical packer with removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

ZINC

Dimensions

1/2″ X 3″

13 x 70mm

Standard Zinc Packer

Bottom anti-return valve allows for removal of head prior to final grout set. Most common industry size offers benefits of adequate urface area for grip with economical price. Suitable for PU, EP, polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard

STEEL

3/8” x 4.5”

10 x 115mm

SLS Signature Line Steel Packer Medium Long

SL Line Packer of highest quality and durability. This heavy duty injection packer is produced to the most discerning standards resulting in a heavier, more resource intensive built and higher production costs. The SLS Mechanical Packers are primarily used in high profile injection jobs and for applications where high injection volumes and pressures require a steel type button head packer with a high flow rating.

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STEEL

1/2” x 4.5”

13 x 115mm

SLS Signature Line Steel Packer Medium Long

SL Line Packer of highest quality and durability. This heavy duty injection packer is produced to the most discerning standards resulting in a heavier, more resource intensive built and higher production costs. The SLS Mechanical Packers are primarily used in high profile injection jobs and for applications where high injection volumes and pressures require a steel type button head packer with a high flow rating.

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STEEL

1/2” x 4.5”

13 x 150mm

SLS Signature Line Steel Packer Long

SL Line Packer of highest quality and durability. This heavy duty injection packer is produced to the most discerning standards resulting in a heavier, more resource intensive built and higher production costs. The SLS Mechanical Packers are primarily used in high profile injection jobs and for applications where high injection volumes and pressures require a steel type button head packer with a high flow rating.

Removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Optional buttonhead fitting available. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STEEL

1/2” x 7”

13 x 170mm

SLS Signature Line Steel Button Head Packer Long

SL Line Packer of highest quality and durability. This heavy duty injection packer is produced to the most discerning standards resulting in a heavier, more resource intensive built and higher production costs. The SLS Mechanical Packers are primarily used in high profile injection jobs and for applications where high injection volumes and pressures require a steel type button head packer with a high flow rating. The buttonhead with large ball valve permits high product volume flow and offers most secure and stay in place connection and reduced leakage at coupler.

Removable anti-return valve in buttonhead fitting on top allows for port-port travel technique. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STEEL

3/4” x 7”

19 x 170mm

SL Line Steel Buttonhead Packer. Large Diameter / Long

SL Line Packer of highest quality and durability. This heavy duty injection packer is produced to the most discerning standards resulting in a heavier, more resource intensive built and higher production costs. The SLS Mechanical Packers are primarily used in high profile injection jobs and for applications where high injection volumes and pressures require a steel type button head packer with a high flow rating. The buttonhead with large ball valve permits high product volume flow and offers most secure and stay in place connection and reduced leakage at coupler.

Removable anti-return valve in buttonhead fitting on top allows for port-port travel technique. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

PLASTIC INJECTION PACKER | PLASTIC PORT

PLASTIC

Dimensions

5/8” x 4″

High Volume Easy Flow Packer | EZ Flow Packer Design

Button Head Packer also known as Progressive Screw Injector.

Plastic packer with large inner diameter for high volume product flow. Recommended for curtain and bladder injection. The packer is threaded and equipped with a removable, sleeve for good grip. Free-floating large ball valve for high volume applications. Buttonhead top for secure connection and minimal leakage. Suitable for PU grouts, Acrylate Gels (Acrylic Gels). Also available with zerk fitting.

Bestseller – a SealBoss Standard

PLASTIC INJECTION PACKER | PLASTIC PORT

PLASTIC

Dimensions

3/8” x 3″

Hammer-In Packer, aka Bang-In Packer, Drive-In Packer and Hammer Blow Injector | EZ Style Design

Basic plastic ez style design with removable return-valve design offers a simple, yet functional packer solution. Suitable for lower pressure injections for PU and EP grouts.

Bestseller – a SealBoss Standard

CUSTOM

We produce custom size packers to specification

Please call if you need custom size packers for unique applications.

PLASTIC

Dimensions

1” x 2″

Surface Port Plastic with Zerk Fitting | Heavy Duty – High Pressure Injection

Very sturdy plastic design suitable for pressure injections with Epoxy and other grouts.

PLASTIC

Dimensions

1” x 2″

Epoxy Injection Port Nozzle – Industry Standard Bestseller

Durable plastic design surface mounted port suitable for epoxy injections. Tri-Base design with perforation holes for best possible adhesion with SealBoss 4500 Epoxy Paste Adhesive. Caps included. For EP grouts.

Bestseller – a SealBoss Standard

PLASTIC

Dimensions

1” x 2″

Epoxy Injection Corner Port Nozzle

Durable plastic design corner surface port suitable for epoxy injections. Corner base design with perforation holes for best possible adhesion with SealBoss 4500 Epoxy Paste Adhesive. Caps included. For EP grouts.

PLASTIC

Dimensions

1/4” x 2.5″

Epoxy Injection Drill Hole Mount Port

Durable plastic port designed to fit 1/2″ drill hole for higher injection pressures than regular surface ports. Suitable for epoxy injections. Caps included. For EP grouts.

STEEL

High Quality Steel Zerk Coupler for Zerk Type Mechanical Packers and Ports for secure connection

The secure fit SealBoss ZC Zerk Coupler for zerk type mechanical packers and ports. This zerk fitting coupler is made from steel and equipped with 4 (four) steel claws/prongs/jaws.

STEEL

Button Head Coupler | Slide Coupler for most secure and tight fit

Recommended for overhead applications, one man operations and for any critical area injection. Steel and Aluminum versions available.

STEEL

Standard Zerks | Low Pressure Zerks

Zerk fittings / grease nipples available in various sizes and designs to fit various packers. Standard Zerks equipped with a spring loaded ball valve and Low Pressure Zerks with a ball only valve.

STEEL

SealBoss Button Head Fitting | Steel | Standard Design

Button head fittings, slide on fittings, for mechanical packers.

SealBoss Hose Sets

Dimensions

Standard lengths

3m / 9 ft

5m / 15 ft

10m / 30ft

Hose Sets | Valves | Accessories

How to Securely Connect Your Pump to The Injection Packer

Equip your injection pump with high quality, pressure tested and approved injection hose sets. Sets include premium pressure hoses, connectors, valves, flexible extension hoses and couplers to securely connect to your packer system.

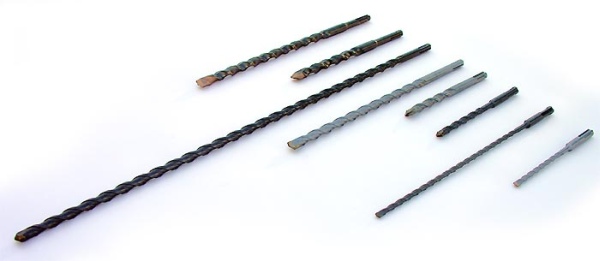

STAINLESS STEEL

Dimensions

12″

36″

60″

Stainless Steel Injection Needles

SealBoss Injection Needle for specialty grouting applications and product delivery into soil substrate, through small holes, Oakum Soakum Injection Technique and more. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

STAINLESS STEEL

Dimensions

12″

36″

60″

Carbide

Maximum Life Drill Bits

Selected, Quality Tested Long Life Drill Bits

Maximum Life, Premium Carbide

Tipped Hammer Drill Bits to fit SDS Plus Style Mounting

We added selected quality drill bits to our line of accessories to save you money and ease the job. Please call our office at 714-662-444 for more information on these competitively priced maximum life drill bits.

- OVERVIEW Page: Mechanical Injection Packers, Surface Mounted Ports, Couplers

- SealBoss ® 13-60S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 13-60S Button Head Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 13-115S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 13-115S Button Head Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 13-175S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 13-175S Button Head Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-60S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-115S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-70 EZ-FIT Steel Injection Grout Packer | Page & Video

- SealBoss ® 16-70 EZ-FIT Button Head Steel Injection Grout Packer | Page & Video

- SealBoss ® 16-60S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-60S Button Head Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-115S Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 16-115S Button Head Steel Mechanical Injection Packer | Page & Video

- SealBoss ® 6-46B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 8-50B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 10-60B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 10-105B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 10-200B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 10-300B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 13-70B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 13-100B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 13-200B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 16-70B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 16-200B Brass Mechanical Injection Packer | Page & Video

- SealBoss ® 10-80 AL Aluminum Mechanical Injection Packer | Page & Video

- SealBoss ® 10-100 AL Aluminum Mechanical Injection Packer | Page & Video

- SealBoss ® 13-80 AL Aluminum Mechanical Injection Packer | Page & Video

- SealBoss ® 13-100 AL Aluminum Mechanical Injection Packer | Page & Video

- SealBoss ® 13-70 ZI Zinc Mechanical Injection Packer | Page & Video

- SealBoss ® 5/8BH Button Head | Hammer In | EZ Flow Plastic Injection Packer | Page & Video

- SealBoss ® 5/8BH Zerk | Hammer In | EZ Flow Plastic Injection Packer | Page & Video

- SealBoss ® 3/8 Hammer In Plastic Injection Packer | Page & Video

- SealBoss ® Surface Mounted Plastic Port with Zerk Fitting | Page & Video

- SealBoss ® Epoxy Port | Surface Mount Plastic Tri Base Port | Page & Video

- SealBoss ® Epoxy Corner Port | Surface Mount Plastic Corner Port | Page & Video

- SealBoss ® Epoxy Port | Drill Hole Recessed Mount Surface Port | Page & Video

Packer Materials & Types

Mechanical injection packers and injection ports are the gateway to successful injection. There are two primary categories of packers available. Insertable mechanical packers and surface mounted ports. SealBoss mechanical packers for grouting are made from steel, brass, aluminum, zinc, various metal alloys and plastic. There are important differences in design and functionality for a variety of products, substrates and objectives. Contractor preferences and comfort levels are also a deciding factor.

Premium mechanical packers feature a rubber sleeve with a threaded shaft. As the threaded shaft is tightened, the rubber sleeve is compressed, creating a compression seal inside the drill hole. A medium soft, ‘made to stick’ rubber that evenly expands diameter while compressed provides the best grip and highest possible injection pressures.

Steel

SealBoss offers many heavy-duty steel crack injection packer variations. Steel offers the most strength and good resistance to oxidizing components found in acrylate/acrylic gels. SealBoss offers a wide variety of steel packers to suit all injection needs. Most packers are equipped with a rubber sleeve, some have a larger washer on the top of the packer to assist in the installation.

Brass , Aluminum, Zinc

Brass, aluminum & zinc packers are economical alternatives to steel packers with similar functionality. The overall strength is lower than steel, brass, zinc and aluminum packers bodies are softer. In some designs, the shaft can be broken off by hammer after injection thus leaving a flush surface. This is an advantage if removal of packer prior to patching is not specified.

Plastic

SealBoss Plastic packers come in many versions. Some permit low resistance, high volume product flow and very quick installation.

Zerk Fitting or Button Head / Button Top

Packers are often equipped with either a zerk fitting or a button head as connective mechanism. The zerk type is most commonly used. It easily connects and disconnects and works with medium to high injection pressures. The button head type can be of advantage in high volume applications and it offers a superior connection which is helpful for single operator injection, over head and large applications.

The SealBoss 5/8” (16mm) Button Head packer offers high volume flow with a button head (button top) coupler to minimize leakage. Insert the plastic sleeve in the drill hole and thread the plastic packer into the sleeve for a compression fit via the hex button head. Anti return valve: A steel ball placed in the shaft of the packer prevents product back-flow.

Hammer-In / Bang-In

The SealBoss Hammer-In port (Bang In Packer) is 3/8” (10mm) or 1/2” (13mm). The ports are inserted into the drill hole with the tap of a hammer. These packers do away with the sleeve and compression sleeve mechanism as the plastic body of the packer itself creates a compression seal. The packers are set very quickly increasing productivity on the job site. Due to the lower friction fit, injection pressures are limited with this packer type.

Diameter, Length, Valves

Diameter

Various factors including the volume targeted for pumping, the depth of drilling, intended injection pressures, as well as aesthetic and other criteria, influence the selection of the packer size. Packers, designed for placement into pre-bored holes in materials such as concrete or rock, are selected to match the diameter off the drill holes.

As a rule, and in addition to the packer material, a larger mechanical packer diameter permits higher injection pressures. 5/8” (16mm), ½” (13mm), 3/8” (10mm) and 1/4” (6mm) are most common diameters for man made structures such as concrete substrates and seem to be the best compromise in strength and size and can be called a standard.

Larger diameters are mostly utilized in rock and other natural structures as found in tunnel and mining applications.

Caution: Packers and ports can exit the drill hole at high velocities under pressure. Correctly installed packers of the right dimensions will minimize this probability. In general, larger diameter packers prevent blow-out better than smaller packers.

The size of the drill hole equals the diameter of the packer. We discuss diameters and drilling angles and techniques in detail in our 1-2-3 at 45 Degree Crack Injection Guideline.

Length

The shaft of the mechanical packer needs to be embedded sufficiently deep within the drilled hole to establish an effective compression seal in the substrate. This depth also prevents spalling of the substrate during the installation and injection processes. For more fragile substrates or deteriorated concrete, we recommend using longer packers ranging from 4″ to 6″ (10-15 cm).

During the injection phase, the drilled hole serves as a conduit for the injected product. In instances where the contractor needs to bridge a substrate gap, a longer shaft length can be beneficial. To accommodate such scenarios, SealBoss offers specially designed packers with extended lengths, enabling the accurate delivery of the material to a specific location within the substrate.

Top Mounted Valve Placement

Two types of top-mounted valves are commonly used: zerk-valves and button-head (also known as button-top) valves. Of the two, button-head valves provide a more reliable connection with the least amount of leakage. Certain top-mounted zerk valves are supplied separately, which allows for the observation of injection grout’s port-to-port grout travel during the injection procedure. As soon as the material starts leaking from the succeeding packer(s), the contractor promptly installs the valve.

Bottom Mounted Valve Placement

Valves installed at the bottom or on the stem enable the removal of the packer’s top section shortly after injection, while maintaining the seal of the drilled holes. This arrangement facilitates the patching of the hole with the remaining part of the packer still embedded in the substrate. As a general guideline, packers should not be removed until the injected product has fully cured to ensure the most effective seal.

Surface Ports

Surface ports, which are often utilized for epoxy injection, provide a surface-mounted alternative to packers. They are ideal for situations requiring lower injection pressures or when drilling into the substrate is unfeasible.

These ports are either glued directly to the surface or positioned within a drilled hole. Many of them feature an open or valve-free design to accommodate quick-release connectors, offering a multiple port injection solution. Generally, surface ports come with caps to hinder epoxy backflow, ensuring a clean and efficient injection process.

For applications requiring a firm fit under higher injection pressures, surface ports with zerk fittings are also available. In addition to these, we offer corner ports, specifically designed for installation in 90-degree construction corners.

Conclusion

In summary, we typically advise starting with the 1/2″ (13mm) mechanical packers when determining the most suitable packer for your project.

Steel packers, possessing superior strength, are the go-to choice for very high injection pressures. However, based on economical factors, budget, and site-specific conditions, they may be more robust than necessary.

A larger packer diameter enhances the packer’s grip within the drilled hole, which is advantageous when dealing with extremely high injection pressures. Best practice dictates to always have larger diameter packers readily available, particularly for scenarios when drill holes inadvertently exceed the planned size.

For steep angle drilling, deteriorated concrete, uneven surfaces, and very high injection pressures, we strongly recommend longer packer sizes.

If your project requires a high product flow at lower pressures, the 5/8″ button head packers consistently deliver excellent results. For low-pressure scenarios in high-quality concrete, the 3/8″ Hammer-In packer is an ideal choice, though precise, round drill holes are crucial for a secure fit.

It’s essential to remember the criticality of a robust and reliable fit of the packers for the technician’s safety and the overall success of the injection work.

For specialized applications, we offer a range of modified packer and port designs. These include surface ports equipped with a zerk fitting for the use of single-component injection systems for smaller epoxy and polyurethane jobs, Injection Screws tailored for the SealBoss Injection Tube Systems for cold joints, and other specialized packers.