Online Training

SealBoss ® Six Part Online Self-Guided Training

Thank you for your interest in our products and certification. This certification is a very valuable and sometimes necessary tool when bidding and starting jobs which call for our materials. The standard charge is $600 for the certification. Please ask for a discount when combined with larger orders.

Moving forward, the easiest way to go about online training is to cover each product set individually. We will start with the polyurethanes. Please refer to the following links and read the guidelines for a more in depth view of these products and the differences between grout type, pumps, and packers in detail.

If you are looking for specific information check out our Search function found in the menu header.

Informative Media is also found here:

Part 1: Polyurethanes, Acrylates – Water Stop Foams and Leak Sealing

Thank you for your interest in our products and certification. This certification is a very valuable and sometimes necessary tool when bidding and starting jobs which call for our materials. The standard charge is $600 for the certification. Please ask for a discount when combined with larger orders.

Moving forward, the easiest way to go about online training is to cover each product set individually. We will start with the polyurethanes. Please refer to the following links and read the guidelines for a more in depth view of these products and the differences between grout type, pumps, and packers in detail.

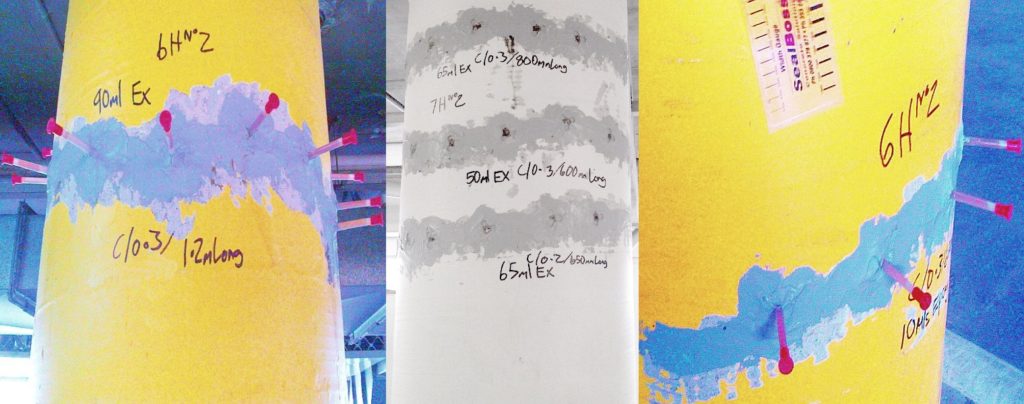

Choosing the correct polyurethane grout for concrete injection can be difficult. It is very important to understand the difference between Hydrophobic and Hydrophilic grouts.

Hydrophobic grouts will completely deter water once it is in its’ cured state. It may require water to initiate the reaction, but the cured product is entirely resistant to moisture. Hydrophilic, on the other hand, will actually expand and contract depending on the water content in it’s’ environment. This being said, we only recommend these materials in environments that have a constant water source. (e.g. seawalls, or below grade basement wall repair where we can’t pinpoint a specific crack. We would inject hydrophilic in a grid pattern to form an expanding and contracting “curtain membrane” on the positive side of the wall.) When hydrophilic materials become completely dry, they harden and lose some of their properties when exposed to water again in the future.

Hydrophobic materials, however, will remain in the same cured state for decades without needing water contact of any kind.

SealBoss 1510 Water Stop Foam , 1570 Water Stop Foam, 1400 Line of LV-Resins, 1570 LV Water Stop Foam, and 1600 Structural-Foam are hydrophobic polyurethanes, while FlexGel and the 2400 Line of Acrylates are hydrophilic polyurethanes.

Please continue to our ‘Online Product Catalog’ for data sheets on these materials and email me any questions you may have.

Coverages:

1510Water Stop Foam , 1570 Water Stop Foam, 1572 Water Stop Foam, and 1600 Structural-Foam are all expanding materials. Simply multipliply (231 cubic inches) x (expansion rate in data sheet) for the overall coverage per gallon.1400 Line of LV-Resins are non-expanding resins. We get 231 cubic inches/gallon.

FlexGel and the 2000 Line of Acrylates are hydrophilic polyurethanes which will expand and contract based on available moisture. Hydrophilics are characterized by the amount of water they will take on per volume. (e.g. Flexgel2 will take on up to 15 parts water, please refer to data sheets for all ratios.) We also estimate roughly 9 square feet/ gallon for curtain injections.

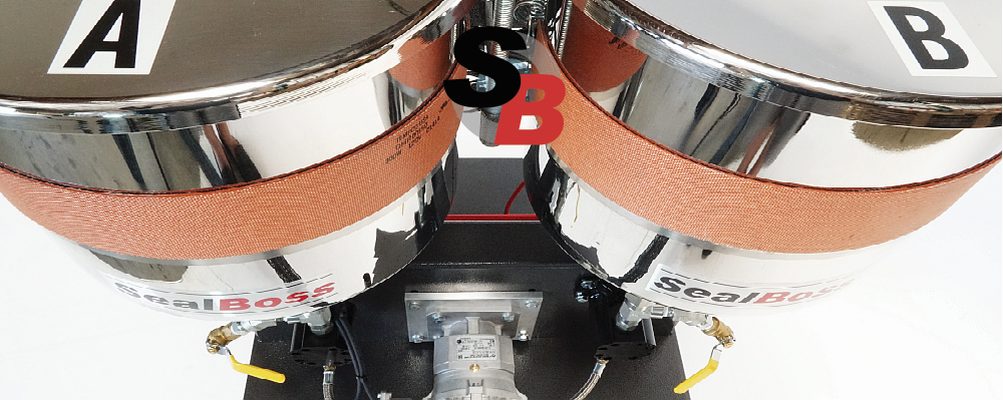

It is also important to understand the pumps, packers, and operating pressures. Most polyurethane grouts can be pumped using a single component high pressure pump. We supply a line of single component pumps. The hoses couple to mechanical packers that are inserted into the wall, floor, or any concrete structure. It is necessary to achieve relatively high pressures as the more material we inject prior to the reaction, the more dense product and more successful repair we have. Some polyurethanes are 2 component mixtures. In these cases, you will most likely want to utilize a 2 component pump. Please keep in mind that if the reaction time allows enough time to inject and flush the pump, single component equipment may be used followed by immediate cleaning procedures.

Please utilize our Online Product Catalog where you can download and print all data sheets for our materials, pumps, and accessories.

Again, please read the articles from the link above, and revert back with any questions concerning polyurethane injection. We cannot possibly explain every aspect of the application in a training document, so we will need you to ask questions if something is not understood or unclear.

If the above link and information is understood, please continue on to Part 2.

Part 2: Epoxies – Structural Repairs

Moving on to the second section of the Online Training, Epoxies. Our epoxies are classified by our 4000 line of products. Epoxies are mainly used for structural repairs.

SealBoss 4500F QuickSeal Epoxy Paste is a 1:1 ratio epoxy used as a surface sealer for most applications as well as an adhesive for securing the surface ports to the crack or void. The product comes in 1 gallon sizes or 22 oz. cartridges.

Important Note: Most Epoxies should be applied in a dry environment.

SealBoss 4040 LV / 4050 SLV are 2:1 ratio injection resins offered in bulk and in cartridges. The LV stands for low, slv for super low viscosity and this is very effective in hairline and small crack injection. In these applications we will surface seal the crack with SealBoss 4500F while also placing surface ports along the crack spaced every 4”-12” depending on crack thickness. After the surface seal has completely cured, we can then connect the cartridge static mixer to the surface port through a series of quick disconnects and nylon tubing, all of which we supply.

SealBoss 4040 LV / 4050 SLV is also offered in 5 gallon bulk containers. It is also a 2:1 ratio product. For the aplication of this product we recommend the SealBoss PA3000 or SealBoss PA3003 epoxy pump. These pumps come set at a 2:1 ratio, but can easily be changed to 1:1 for other materials by changing the piston assembly. The same application of surface seal and surface ports apply here. You can find all data sheets for the materials and pumps in the Online Product Catalog.

Coverages:

SealBoss 4500 QS, 4040 LV / 4050 SLV , and 4040 are all non-expanding products. These are all estimated on a coverage of 231 cubic inches/gallon.

22oz. SealBoss 4500 QuickSeal: 40 cubic inches

34oz. SealBoss 4040 LV / 4050 SLV : 70 cubic inches

As with the first section, please take a look at the above links and look over anything in reference to epoxy injection. If you have any questions about the links or data sheets, please let us know.

Part 3: Polyurea / Polyurethane – Floor Repair

The third section of the Online Training covers Polyurea Products which are classified by our 6000 line. Polyureas are offered in cartridge form as well as 5 gallon and 55 gal. bulk containers. The very short cure time makes them very convenient for quick repairs.

SealBoss 6000, 6060 are 2 component, fast-set, rigid 1:1 ratio polyurea. Products are 100% solids, solvent free and of very low odor. These products are used for for cracked and chipped concrete referred to as spall repair. The viscosity of this product is very low, which makes it only useful for horizontal applications. It is most commonly used in warehouse floors where heavy fork lift traffic is present. Because of the quick cure time, repairs can be made and traffic over that area can resume in a matter of minutes. Sand can also be added to cut down on material cost, increase compressive strengths, and provide longer working times.

SealBoss 6500 is a 2 component, fast-set, flexible polyurea. It is also a 1:1 ratio material. We typically recommend this product for control and expansion joints where movement will be experienced. It is also available in cartridge and bulk containers. It is most commonly used in control joint filling in new construction. Similar to 6060, these joints can be filled, and the floor can be finished the same day, saving the contractors valuable time and money. 6500 bulk systems are pumped with the SealBoss JointMaster Pro2 polyurea pump. Data sheets can again be found in the Online Product Catalog for the materials as well as the pump.

SealBoss 6500 HM is a hand mix material which provides the applicator additional working time to mix and apply the materials. It is extremely convenient in hot temperatures and areas which cannot be applied by cartridges.

Polyureas are gaining popularity in the United States as well as world wide. The convenience of the fast-set nature of the product saves a lot of time and money. Please let us know if you have any questions about the polyurea line or the pump.

Part 4: Specialty Coatings

Please refer to the coating link above for information on our specialty coatings.

Part 5: Cartridge System

Many Sealboss products are availble in cartridges. Please refer to the cartridge link above for information on our cartridge system.

Part 6: Pumps and Equipment

One of the most important aspects of our system is not only knowing what material to use, but also knowing what equipment to use for each material.

No matter if you are faced with a minor basement leak or a major tunnel gusher of large hydrostatic pressure , SealBoss has you covered. You need to have the right tools at hand to achieve the results. SealBoss infrastructure repair pumps provide you with tried and true concrete solutions.

SealBoss ® offers a wide variety of pumps for crack injection, slab lifting, soil stabilization, soil compaction and floor repair.

Please refer to the following links above for a more in depth view of these products and the differences between grout type, pumps, and packers in detail.

As for the accessories, we carry one of the largest selections of injection packers. We these mechanical packers in diameters from 1/4″ to 1″ and lengths from 2″ to 12″ in a variety of materials such as brass, steel, aluminium, zinc, platics. Custom order sizes are available.

We offer a full line of specialty drill bits proven to ease the drill job when placing packer holes in concrete. Along with the surface ports, pump parts, and cartridge systems, we offer a one stop shop for many concrete repair and waterproofing needs. Please take a look at the last couple of links below, and if you have no questions, please proceed to the certification exam which will be returned and kept on file.

We take pride in our customer service, so please feel free to call or email anytime with questions or needs. Good luck with the exam, and we look forward assisting you on all of your upcoming projects!

Please don’t hesitate to contact us with any questions.

Exam

Consider In-House Training at Your Facility or at SealBoss

SealBoss ® In-House Training Is Informal, Fun, And Efficient